Contractors have multiple cable options for secondary power distribution, but twisted cable like ServicePlex® offers distinct advantages for data center applications.

OPTIMAL CABLE SOLUTION FOR DATA CENTERS

ServicePlex is an assembly of conductors twisted together with a built-in ground to create a consistent, uniform cable configuration. This design effectively functions as a prefab wire pull for improved ampacity rating, easier installation, and cost-savings.

AMPACITY ADVANTAGES PREVENT CABLE DERATING

Ampacity defines how much current a cable can safely handle before heat becomes a problem, and a cable's construction plays a key role in how heat is managed. In space-constrained data centers, jacketed tray cable and single conductors may exhibit poor heat dissipation.

Per NEC, poor heat dissipation requires cable derating (lowering the safe operating ampacity of a conductor). In higher ambient temperatures, 500 amp cable may be derated to 400 amp in order to maintain safe operation. This leads to situations where cables with higher ampacity ratings are purchased, increasing weight, material & labor costs.

ServicePlex offers higher capacity per conductor. The cable's twisted design optimizes spacing for thermal performance, eliminating the need for derating. This creates significant practical advantages. For example, a circuit requiring 400 amps could use 250 Kcmil, 3 conductor ServicePlex (SPLEX250/3), a lighter and more flexible cable, instead of 500 Kcmil, 3 conductor tray cable (TCXH500/3), resulting in significant cost & labor savings.

SAVES ON TRAY SPACE & INSTALLATION TIME

Tray space is often the limiting factor in data center power distribution. Single conductors require physical separation, and tray cable's thermal performance forces multiple parallel runs. Both approaches consume excessive tray space relative to their capacity.

By contrast, ServicePlex allows up to 30% more conductors in the same tray space. The twisted cable keeps all conductors uniform, and the integrated ground eliminates separate ground management. This maximizes existing cable tray critical in retrofit installs and expansions.

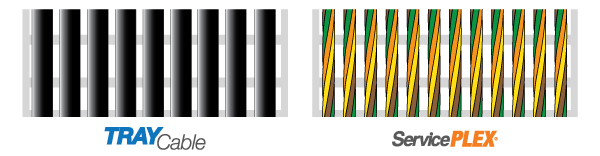

The illustration shows 750 Kcmil jacketed tray cable and 500 Kcmil ServicePlex in 48” cable tray. For cable tray this size, NEC spacing requirements allow 9 tray conductors with 2.7” spacing or 12 ServicePlex assemblies (36 total conductors) with 2” spacing. With ServicePlex, the result is faster installation, reduced crew fatigue, and a more organized appearance.